Dyeing challenges caused by differences in fiber properties of polyester-ammonia knitted fabric

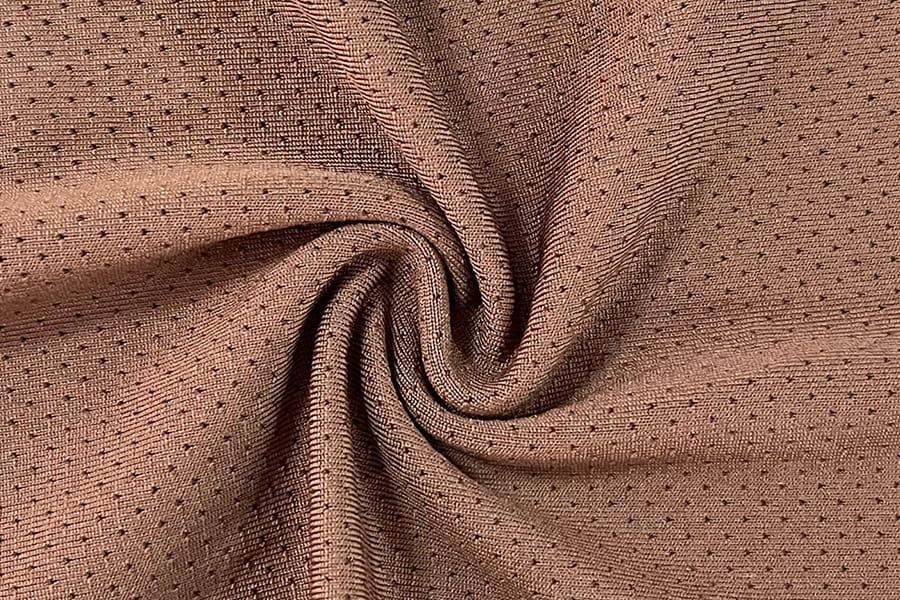

Polyester-ammonia knitted fabric is widely used in high-end clothing and functional clothing due to its excellent elasticity and comfort. Nantong Tongchunlong Textile Technology Co., Ltd., with its strong R&D team and complete industrial chain, faces many dyeing challenges in the R&D and production of polyester-ammonia knitted fabric. These challenges mainly stem from the differences in the physical and chemical properties of the two fibers, polyester and spandex.

Polyester and spandex have very different requirements for dyes. Polyester requires the use of disperse dyes at high temperatures, while spandex may require reactive dyes or acid dyes, which brings challenges to the design of dyeing processes.

Double dye method: In order to meet the dyeing needs of the two fibers, the double dye method is often used. This method dyes polyester first and then spandex, but the use of different dyes and the selection of dyeing order need to be carefully adjusted to prevent color difference and uneven dyeing.

Dye compatibility: The compatibility issues of different dyes will also affect the final dyeing effect. If incompatible dyes are selected during the dyeing process, it may cause color confusion or fail to form the expected color effect.

Difficulty in temperature control

Temperature is one of the key factors affecting dyeing quality. Polyester usually needs to be dyed at high temperatures, while spandex is extremely sensitive to high temperatures.

Risks of high-temperature dyeing: When dyeing polyester, it needs to be carried out in a high-temperature environment of 120°C to 130°C. Although this temperature is suitable for polyester, it may cause thermal degradation and elasticity loss for spandex, thus affecting the overall performance of the fabric.

Limitations of low-temperature dyeing: Although low-temperature dyeing can protect the elasticity of spandex, this method may cause incomplete dyeing of polyester and uneven color. Therefore, it is particularly important to find the temperature balance point during the dyeing process.

Mechanical stress and tension management

During the dyeing process, the mechanical stress and tension of the fabric will significantly affect the dyeing effect and elastic performance of spandex.

Stretching during dyeing: During the dyeing process, if too much stretching force is applied to the fabric, the spandex may be deformed due to elastic fatigue, resulting in damage to the shape and performance of the final fabric. Excessive stretching may also affect the uniform penetration of the dye.

Shrinkage and deformation: Dyeing treatments at different temperatures and humidity may cause the fabric to shrink or deform, and this change may cause size mismatch and shape distortion in the finished product.

Color fastness and stability issues

The color fastness after dyeing (light fastness, washing fastness, friction resistance, etc.) is directly related to the service life and market acceptance of the fabric. Polyester-spandex knitted fabrics face many challenges in this regard.

Risk of reduced color fastness: Since spandex is easy to fade under high temperature and high humidity conditions, dyed polyester-spandex knitted fabrics may have obvious color differences and fading under conditions such as washing and light.

Insufficient post-processing technology: If there is a lack of effective color fixing technology in the post-dyeing process, the binding force between the dye and the fiber is insufficient, which can easily lead to reduced color fastness.

English

English 中文简体

中文简体 русский

русский Español

Español