How to improve the UV resistance of nylon ammonia knitted fabric?

With the increasing awareness of outdoor activities and sun protection, especially in the fields of sportswear, outdoor clothing and swimwear, consumers have put forward higher requirements for the UV resistance of fabrics. Nylon ammonia knitted fabric is widely used in these fields due to its high elasticity, lightness and comfort. However, nylon and spandex fibers themselves are relatively weak in their resistance to UV rays.

Specific methods to improve the UV resistance of nylon ammonia knitted fabric

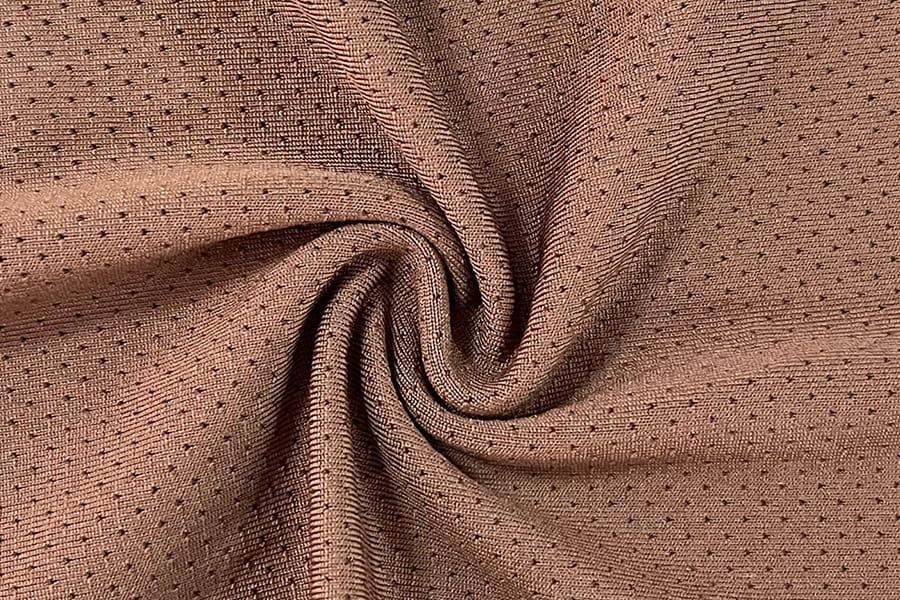

Features high-density knit construction

Increasing the density of nylon ammonia knitted fabric can significantly improve its UV resistance. The density of the knitted structure determines how easily UV rays can penetrate the fabric. Higher fiber density and a tighter fabric weave make it more difficult for UV rays to penetrate the fabric, thereby enhancing its protective effect.

Technical realization: By adjusting the knitting process, the tightness between fibers is increased. Process optimization can be carried out with the help of its powerful weaving production line. For example, warp knitting technology can be used, which can provide higher fabric density than weft knitting technology, thereby improving UV resistance.

Expected effect: Increase fiber density and fabric tightness, enabling basic physical level UV protection. Although this cannot completely block UV rays, it can be used as a basic means to increase the UPF value of the fabric.

Add UV absorber

UV absorbers are the main chemical means to improve the UV resistance of fabrics. Nylon and spandex fibers themselves have limited ability to absorb ultraviolet rays. By introducing ultraviolet absorbers during the fabric production process, they can effectively block ultraviolet radiation.

Common UV absorbers: Organic UV absorbers such as benzotriazole and hydroxybenzophenone absorb and neutralize UV rays, converting them into harmless heat energy. This type of absorbent can be fixed on the surface of the fabric or inside the fiber by dyeing or coating to provide continuous UV protection.

Inorganic ultraviolet absorbers: such as zinc oxide and titanium dioxide. These substances have excellent ultraviolet reflection and absorption capabilities in the form of microparticles, and can widely cover UVA and UVB bands. Titanium dioxide is particularly good at reflecting UVB, while zinc oxide can deal with both UVA and UVB. Evenly distributing these inorganic particles on the surface of nylon spandex fiber or fabric can significantly improve its UV resistance.

Application method: Add UV absorbers to nylon ammonia knitted fabric through dipping or coating process. In dyeing and coating lines, these absorbents can be applied flexibly to ensure that they are tightly integrated with the fibers and avoid loss of protection caused by washing or abrasion.

Applications of Nanotechnology

The introduction of nanotechnology provides a new way to improve the UV resistance of nylon ammonia knitted fabric. Nanoscale titanium dioxide and zinc oxide particles can be more evenly distributed on the surface of the fabric without affecting the fabric's feel and breathability.

Advantages: Nanoparticles have an extremely high surface area and are able to reflect and scatter UV rays more efficiently. Moreover, because the nanoparticles are extremely small in size, they can be tightly combined with fibers and are not easily removed during washing or use, so the protective effect is more durable.

Nantong Tongchunlong Textile Technology Co., Ltd. relies on its profound experience in textile technology research and development, textile raw material processing, and high-end interlining manufacturing, and is committed to providing users with high-quality nylon ammonia knitted fabric.

English

English 中文简体

中文简体 русский

русский Español

Español