Nantong Tongchunlong Textile Technology Co., Ltd. is located in Nantong, Jiangsu Province, which is known as the hometown of textile. It covers an area of 70 acres with a total construction area of 65,000 square metres. Tongchunlong is a large-scale modern integrated manufacturing enterprise with a complete industrial chain integrating textile science and technology research and development, textile raw material processing and high-end interlining fabric manufacturing.

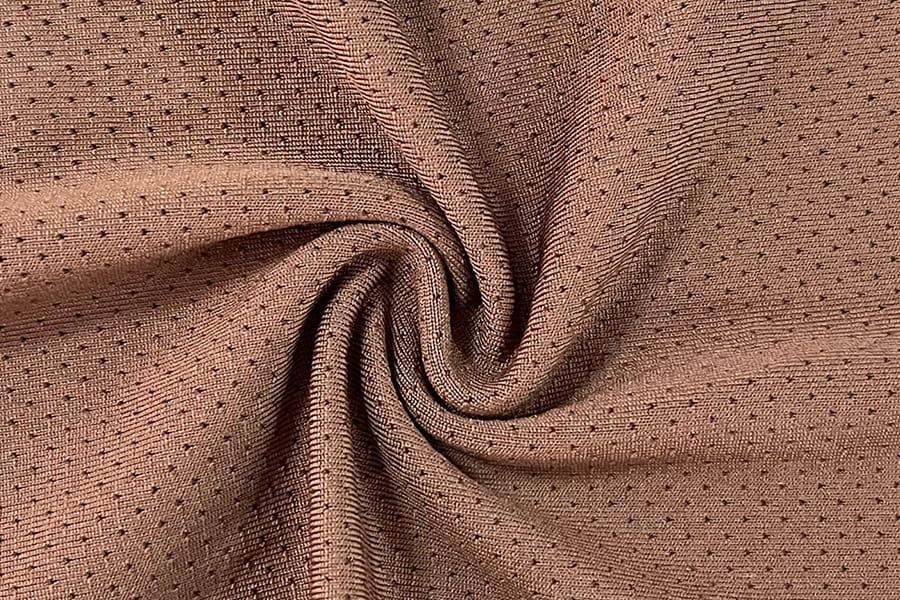

As China Polyester knitted fabric Suppliers and Wholesale Polyester knitted fabric Factory, it has a number of subsidiaries such as Bo Chunxuan Textile, specialising in the research and development and manufacture of high-grade garment fabrics and high-quality interlining fabrics.

English

English 中文简体

中文简体 русский

русский Español

Español