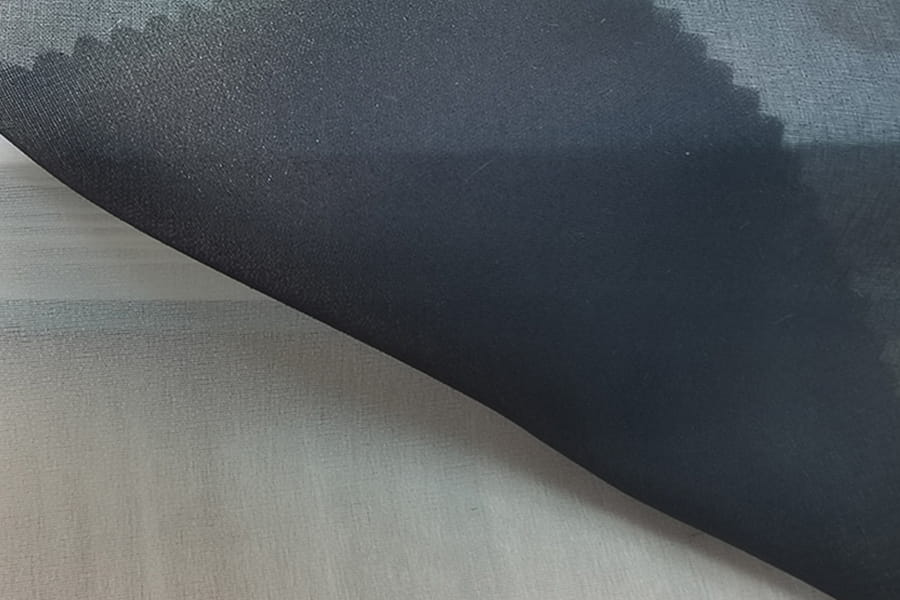

The durability of cotton woven fusible interlining largely depends on its quality, construction, and the conditions in which it's used.High-quality cotton woven fusible interlinings typically feature strong, heat-activated adhesives that bond well to fabrics and maintain their integrity over time. However, lower-quality adhesives may degrade after repeated washing or dry cleaning, leading to peeling, bubbling, or detaching.

Specialized adhesives, such as those that are resistant to water, heat, or chemicals, will help the interlining retain its fusibility and strength after several washes.

If the interlining is properly applied with appropriate heat and pressure, it will typically retain its adhesive strength over multiple washes. However, improper application, like insufficient heat during pressing, can result in weak bonding and a reduced lifespan.

The type of fabric it's bonded to can also affect how long it lasts. For instance, heavier fabrics or those with a high content of natural fibers like cotton may be more compatible and maintain the bond better than synthetic or delicate fabrics.

The interlining's longevity will depend on whether the washing and care instructions are followed correctly. Machine washing or dry cleaning may impact the adhesive if high temperatures or harsh chemicals are used.

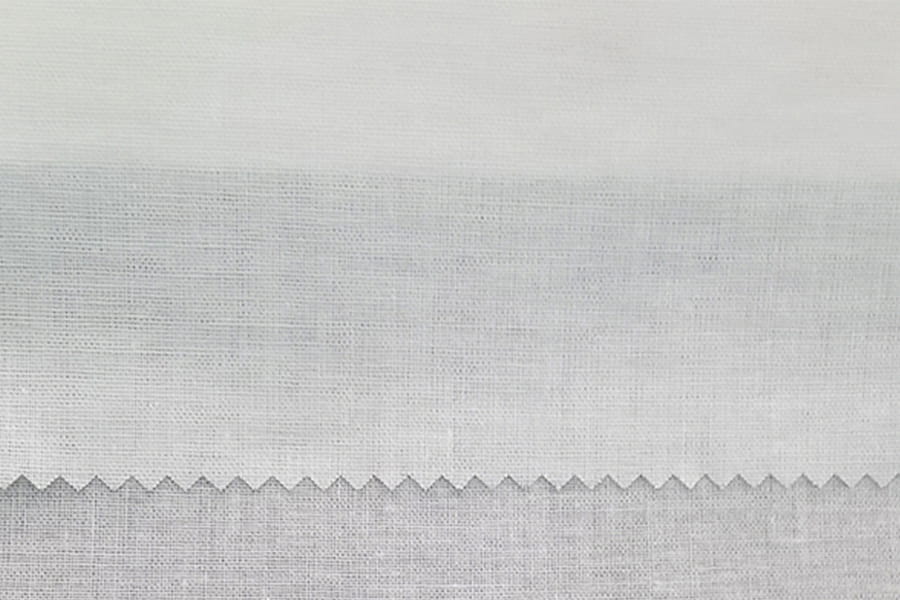

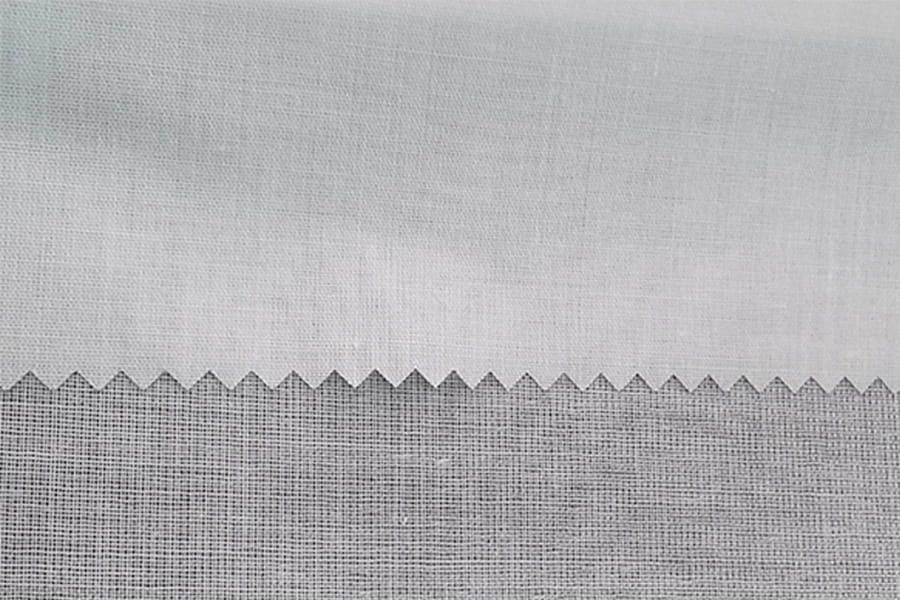

For long-lasting results, it's important to follow the manufacturer's care guidelines, which may recommend cold or lukewarm water washing and gentle cycles for machine washing, or using mild detergents that won't break down the adhesive.After several washes or dry cleanings, some interlinings, especially those made with lower-quality materials, may experience shrinkage or distortion, which can cause the interlining to lose its original shape or adhesion properties.

Cotton woven fusible interlining should be pre-shrunk or treated to minimize shrinkage when exposed to heat or moisture, as excessive shrinkage can affect its performance.

Exposure to high temperatures (either from the washing process or environmental conditions like ironing or steaming) can weaken the adhesive over time, especially if the interlining is not designed for high-heat applications.Dry cleaning can also affect fusible interlinings, depending on the solvents used. Interlinings designed specifically for dry-clean-only garments may perform better in these cases.

In terms of wear and tear, fusible interlining is generally designed for use in areas that don't experience a lot of friction. However, high-stress areas (like elbows, collars, or cuffs) may experience a quicker breakdown of the adhesive bond over time due to repeated bending or rubbing.

Cotton woven fusible interlining can remain long-lasting if it is made from high-quality materials, properly applied, and maintained with care. However, over multiple washes or dry cleanings, the adhesive bond may weaken if care instructions are not followed or if the interlining is exposed to excessive heat, harsh chemicals, or stress. To maximize its lifespan, it’s important to choose a good-quality interlining, ensure proper application, and adhere to the recommended care guidelines.

English

English 中文简体

中文简体 русский

русский Español

Español