What are the considerations for selecting the appropriate weight and width of Polyester Fusible Interlining for specific applications?

Selecting the appropriate weight and width of

Polyester Fusible Interlining is crucial for ensuring optimal performance and compatibility with specific garment applications. Several considerations should be taken into account:

Fabric Type and Weight: The weight of the interlining should complement the weight and thickness of the garment fabric. Lighter weight interlinings are suitable for lightweight fabrics, while heavier weight interlinings provide better support for thicker fabrics.

Garment Style and Design: The style and design of the garment influence the selection of interlining weight and width. For example, tailored garments such as blazers and coats may require heavier weight interlinings for added structure, while lightweight interlinings are suitable for softer garments like dresses and blouses.

Desired Effect: Consider the desired effect or outcome of using the interlining. For example, if the goal is to add subtle shaping and support to a garment, a lighter weight interlining may be sufficient. However, if a more structured look is desired, a heavier weight interlining may be necessary.

Ease of Application: The width of the interlining should be compatible with the construction process and ease of application. Choose a width that allows for efficient cutting and positioning during garment assembly, minimizing waste and ensuring proper coverage.

Durability Requirements: Consider the durability requirements of the garment and select an interlining weight that provides adequate support and reinforcement. Heavier weight interlinings offer greater durability and resilience, particularly in high-stress areas such as collars, cuffs, and waistbands.

Washing and Care Instructions: Take into account the washing and care instructions for the garment when selecting the interlining weight and width. Ensure that the interlining is compatible with the laundering methods and conditions specified for the garment to prevent shrinkage, distortion, or damage.

Fabric Stretch and Recovery: If the garment fabric has stretch properties, choose an interlining that can accommodate and enhance these properties without restricting movement or causing puckering. Consider stretch interlinings or bias-cut interlinings for garments with significant stretch requirements.

Aesthetic Considerations: Evaluate the visual impact of the interlining on the finished garment. Choose an interlining weight and width that provide the desired level of shaping and support without creating bulk or altering the garment's silhouette.

Supplier Recommendations: Consult with the interlining supplier or manufacturer for recommendations on the most suitable weight and width for specific applications. They can provide valuable insights based on their expertise and product knowledge.

Polyester fusible interlining of Features

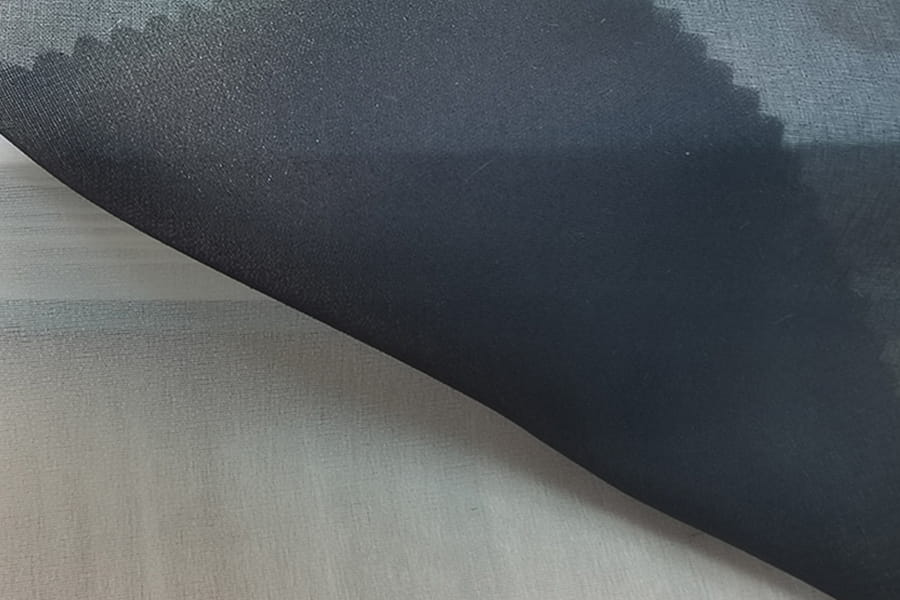

Composition: Polyester Fusible Interlining is primarily composed of polyester fibers. The use of polyester ensures compatibility with all-polyester fabrics and provides excellent strength and durability.

Special Pretreatment Process: The interlining undergoes a special pretreatment process to enhance its bonding capabilities, particularly with difficult-to-bond fabrics. This process prepares the surface of the interlining for optimal adhesion and ensures a strong bond between the interlining and the fabric.

Special Adhesive Powder: Polyester Fusible Interlining is equipped with a special adhesive powder designed to provide strong and durable bonds, even with challenging fabrics such as those with coatings or specialty finishes. This adhesive powder ensures reliable adhesion and prevents delamination or separation over time.

Versatility: Polyester Fusible Interlining is highly versatile and can be used with a wide range of fabrics, including difficult-to-bond materials. Its compatibility with various coatings and finishes makes it suitable for high-end garments and specialty applications where traditional interlinings may struggle to bond effectively.

Slip Properties: The interlining is designed to provide slip, allowing for ease of handling and positioning during garment construction. This ensures precise placement of the interlining and facilitates smooth assembly of garment components.

English

English 中文简体

中文简体 русский

русский Español

Español