1. The Role of Yellowing-Resistant Technology

Yellowing-resistant polyester fusible interlining stands at the forefront of technological innovation within the textile industry. By integrating specialized additives and treatments into the manufacturing process, this interlining surpasses conventional options by offering enhanced resistance to discoloration over time. Advanced UV stabilizers play a pivotal role in shielding the interlining from the detrimental effects of sunlight exposure, which is a primary cause of yellowing in polyester fabrics. These stabilizers effectively absorb or scatter harmful UV radiation, preventing it from penetrating the interlining and causing degradation of the polymer chains. As a result, the interlining maintains its original color and appearance even after prolonged exposure to sunlight, ensuring garment longevity and aesthetic appeal. In addition to UV stabilizers, optical brighteners are another key component in yellowing-resistant polyester fusible interlining. These compounds function by absorbing ultraviolet light and re-emitting it as visible blue light, effectively counteracting the yellowing effect caused by environmental pollutants and aging. By imparting a brightening effect to the interlining, optical brighteners enhance its whiteness and overall color fidelity, resulting in garments that look fresher and more vibrant throughout their lifespan.

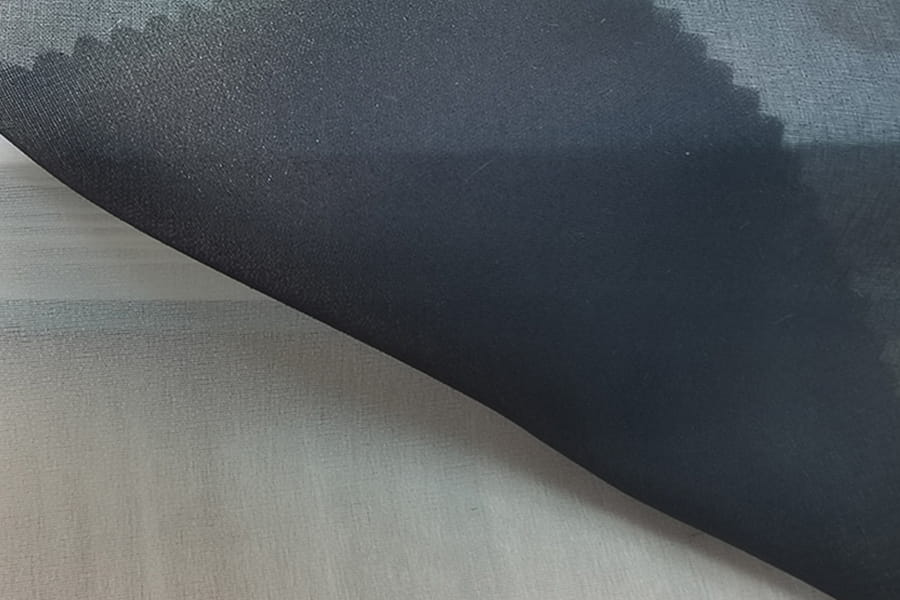

2. Advantages of DTY Yarn Type

Drawn Textured Yarn (DTY) stands out as the preferred yarn type for polyester fusible interlining, owing to its exceptional properties and performance characteristics. Unlike conventional yarn types, DTY undergoes a specialized texturing process that imparts desirable attributes such as elasticity, resilience, and dimensional stability, making it an ideal choice for interlining applications. One of the primary advantages of DTY yarn is its superior fusibility, which enables seamless bonding between the interlining and fabric layers during the garment assembly process. The yarn's uniform texture and consistent quality ensure reliable adhesion, resulting in smooth, wrinkle-free finishes that enhance the overall appearance and structural integrity of the garment. DTY's high tensile strength and durability contribute to long-lasting performance, with interlined garments retaining their shape and form even after repeated wear and laundering. DTY yarn offers excellent dyeability, allowing for vibrant and colorfast finishes that meet the diverse aesthetic preferences of consumers.

3. Applications Across Apparel Segments

Yellowing-resistant polyester fusible interlining finds versatile applications across a wide range of apparel segments, catering to diverse style preferences, performance requirements, and market demands. In outerwear, interlining reinforces critical areas such as collars, cuffs, and pocket flaps, providing structure, shape retention, and durability to garments such as coats, jackets, and blazers. Its ability to withstand environmental stressors ensures that outerwear maintains its pristine appearance and functionality over time, even in harsh weather conditions. Similarly, in sportswear, polyester fusible interlining enhances the performance and comfort of athletic garments by providing support, breathability, and moisture management properties. From reinforcing seams and waistbands to adding stability to activewear panels and inserts, interlining plays a crucial role in optimizing garment fit, function, and longevity, allowing athletes to perform at their best with confidence and ease. In formalwear and intimate apparel, yellowing-resistant interlining contributes to the impeccable tailoring, luxurious feel, and enduring elegance of garments such as suits, dresses, and lingerie. By delivering impeccable draping, smooth finishes, and enhanced comfort, interlining elevates the overall quality and perceived value of these garments, ensuring that wearers look and feel their best on any occasion.

English

English 中文简体

中文简体 русский

русский Español

Español