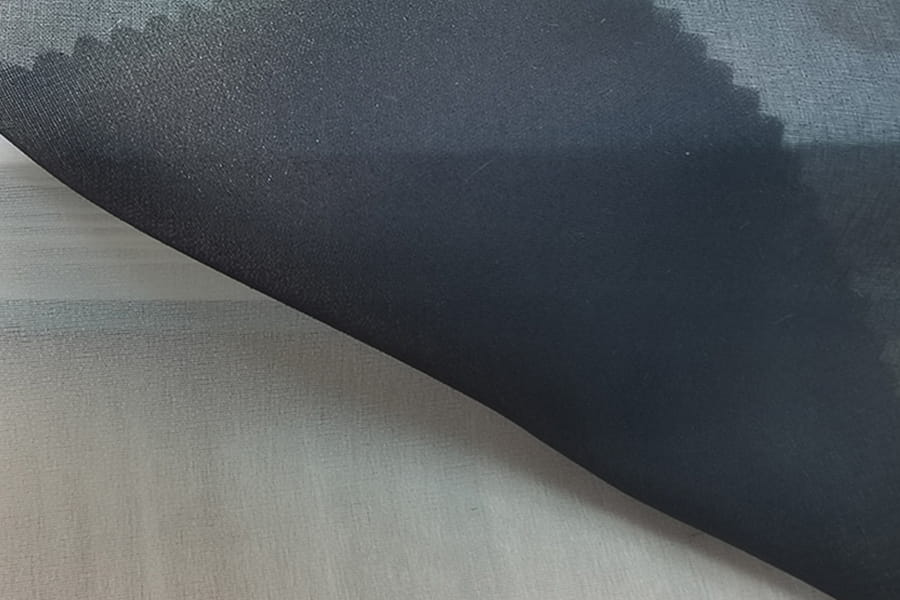

Fusible interlining is a crucial auxiliary material in garment manufacturing, playing multiple roles in the production process. It is used to bond different materials together firmly, thereby enhancing the structural integrity of the garment, improving its appearance, and significantly affecting its texture and comfort.

Functions of fusible interlining in garments

1.Structural reinforcement: In garment manufacturing, fusible interlining is commonly used to reinforce specific parts of a garment, such as the collar, cuffs, pocket openings, and buttonholes. These areas are prone to stretching, pressure, or frequent use and wear, and fusible interlining can provide them with additional support, extending the garment's lifespan. In special types of garments, such as suits, coats, and dresses, fusible interlining is indispensable. It can make the garment more sturdy and three-dimensional, maintaining its shape and lines.

2.Appearance enhancement: Fusible interlining can effectively improve the appearance of a garment. Whether in a display window or during wear, the garment can maintain a flat and neat appearance, giving a good impression. In some garment designs that require specific shapes or outlines, such as stiff collars, stiff sleeves, and stiff skirts, the use of fusible interlining can make these designs more prominent, adding to the fashion sense and design感of the garment.

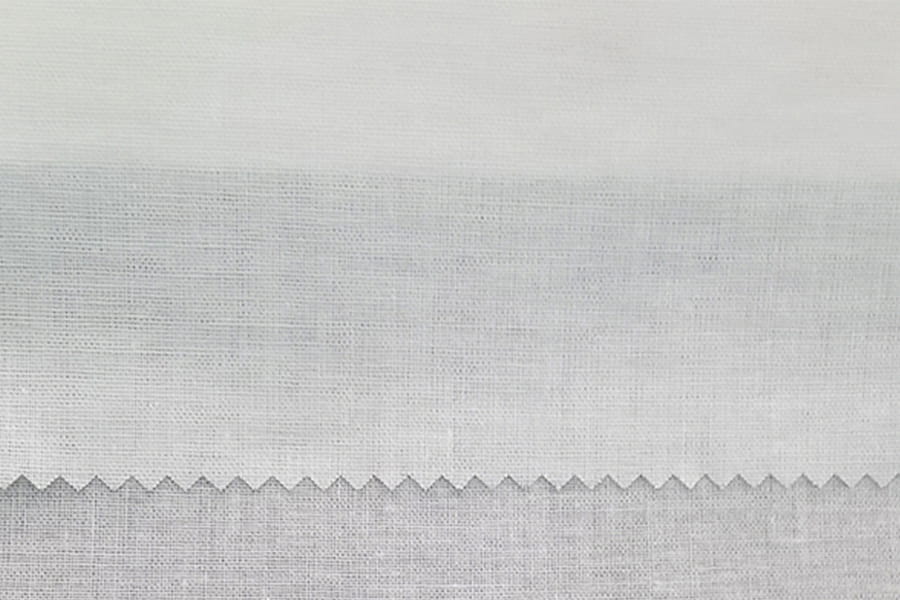

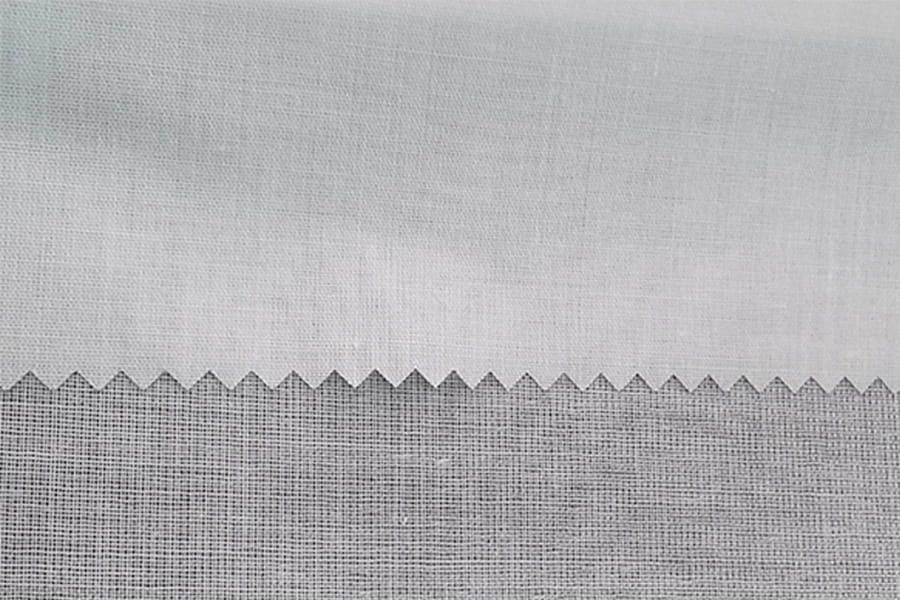

3.Texture improvement: Fusible interlining can not only improve the appearance of a garment but also enhance its overall texture. By properly selecting fusible interlining with soft and delicate textures, the garment can be made more comfortable while maintaining its softness and flexibility. Some high-grade fabrics may be too thin or easily deformed. Adding fusible interlining can increase their thickness and texture, making the garment look more advanced while maintaining the original properties of the fabric.

4.Strengthening detail treatment: Fusible interlining is also commonly used in garment manufacturing to strengthen detail treatments, such as pocket openings and buttonholes. It can make these details clearer and more three-dimensional, improving the overall quality and craftsmanship of the garment. With the use of fusible interlining, garment designers can more freely realize various complex design ideas without having to consider too much the fabric's properties and processing difficulty.

Impact of fusible interlining on garment quality and comfort

1.Quality: The reasonable application of fusible interlining can significantly improve the quality of a garment. It can increase the garment's durability and sturdiness, reduce its deformation and wear, and thus extend its lifespan. Reinforced with fusible interlining, the garment is less likely to become loose or deformed during wearing, maintaining its overall shape and line beauty, and improving the overall wearing experience.

2.Comfort: The choice and use of fusible interlining have a significant impact on the comfort of a garment. The material, thickness, and matching of fusible interlining will directly affect the hand feel and softness of the garment. If the fusible interlining is selected improperly or used excessively, it may make the garment stiff and unbreathable, affecting the wearing comfort. Therefore, when choosing fusible interlining, it is necessary to consider the comfort and ensure that it matches the fabric to maintain the garment's softness and comfort.

Fusible interlining is an important auxiliary material in clothing manufacturing. It has many functions such as structural reinforcement, appearance enhancement, texture improvement, and detail enhancement. The selection and use of fusible interlining has a significant impact on the quality and comfort of the garment.

English

English 中文简体

中文简体 русский

русский Español

Español